Master of Science in Advanced and Intelligent Manufacturing

Master of Science in Advanced and Intelligent Manufacturing

Advanced, Smart, and Digital Manufacturing

The Department of Mechanical and Industrial Engineering offers the Master of Science (MS) in Advanced and Intelligent Manufacturing (AIM) to meet the growing demand for engineers, researchers, and scientists trained in advanced manufacturing and Industry 4.0 technologies.

The advent of the industrial internet of things, additive manufacturing (3D printing) of parts and electronics, advanced materials with unique properties, and efficient manufacturing processes transforms manufacturing operations into advanced manufacturing. Advanced manufacturing focuses on developing innovative technologies to create existing and new products by leveraging novel emerging materials, advanced processes, information, automation, computation, sensing, AI, and digitalization.

Through a curriculum focused on advanced, smart, and digital manufacturing, the MS in Advanced and Intelligent Manufacturing prepares students to be researchers for development of advanced manufacturing technologies, and leaders for managing advanced manufacturing enterprises.

The program is open to students with a Bachelor of Science degree in engineering, science, mathematics, or equivalent field. This degree program offers students an opportunity to either train for industry jobs with coursework and co-op experience or prepare for a doctoral program through coursework and research experience.

Innovative Curriculum - MS in Advanced and Intelligent Manufacturing

Three key curriculum components of the MS in Advanced and Intelligent Manufacturing program are ‘advanced’, ‘smart’, and ‘digital’. These are among the top 10 most promising advanced technologies transforming the global manufacturing industry, according to the U.S. ranking of the Global Manufacturing Competitiveness Index (2016). Within these areas, students learn cutting-edge technologies, including courses on the internet of things, intelligent manufacturing, data analytics engineering, robotics, materials engineering, nano and microscale manufacturing, and additive manufacturing.

Advanced Manufacturing includes conventional manufacturing, additive manufacturing, and nanomanufacturing. Conventional manufacturing covers metal removal, forming, casting, and particulate processes. Additive manufacturing covers topics such as 3D printing of parts using different approaches. Nanomanufacturing includes conventional fabrication as well as printing of micro and nano devices and design and creation of multifunctional materials using automation and scalable processes.

Smart manufacturing focuses on factory automation, process monitoring and control, diagnostics, prognostics and maintenance, cloud-enabled manufacturing, and industrial internet of things for manufacturing performance assurance.

Digital manufacturing leverages real-time data analytics and control systems, advanced high-fidelity models, networked data, and computation for seamless interoperation of cyber and physical assets in manufacturing facilities.

In smart and digital manufacturing, all entities, including people, parts, products, equipment, systems, suppliers, and logistics and transportation systems are connected to achieve enterprise-level efficiency.

An interdisciplinary program with a focus in mechanical and industrial engineering, courses build upon the principles and knowledge in materials science and engineering, mechanical engineering, industrial engineering, computer science, robotics and controls engineering, electrical and computer engineering, and business administration.

Students can complete the master’s degree by pursuing any of the three tracks: coursework option, project option, and thesis option.

Students have robust research opportunities at Northeastern including through its manufacturing infrastructure such as the George J. Kostas Nanoscale Technology and Manufacturing Research Center, the National Science Foundation Center for High-Rate Nanomanufacturing, and the Advanced Nanomanufacturing Cluster for Smart Sensors and Materials. Students are have access to Northeastern’s multidisciplinary research centers and institutes, such as the Institute for the Wireless Internet of Things, the Institute for NanoSystems Innovation, the Institute for Experiential Robotics, and the Institute for Information Assurance. Northeastern also has partnerships with national research labs, who are involved in advanced manufacturing research, and several industry collaborations.

The MS in Advanced and Intelligent Manufacturing is a full time program offered in Boston, on campus.

- Build digital (CAD) models of parts and products to support manual and computer-aided manufacturing.

- Design, develop, and analyze traditional and advanced manufacturing processes and systems.

- Utilize additive manufacturing to produce complex parts with ease and efficiency.

- Design and operate advanced and intelligent manufacturing systems enabled by data analytics, machine learning, cloud computing, and industrial internet of things.

Gordon Institute of Engineering Leadership Certificate

Students may complete a Master of Science in Advanced and Intelligent Manufacturing in addition to earning a Graduate Certificate in Engineering Leadership. Students must apply and be admitted to the Gordon Engineering Leadership Program in order to pursue this option. The program requires fulfillment of the 16-semester-hour curriculum required to earn the Graduate Certificate in Engineering Leadership, which includes an industry-based challenge project with multiple mentors. The integrated 32-semester-hour degree and certificate will require 16 semester hours of advisor-approved Advanced and Intelligent Manufacturing technical courses.

Experiential Learning

Northeastern combines rigorous academics with experiential learning and research to prepare students for real-world engineering challenges.

The cooperative education program, also known as a “co-op,” is one of the largest and most innovative in the world, and Northeastern is one of only a few that offers a co-op program for graduate students. Through this program, students gain up to eight months of industry experience as part of the academic curriculum, giving them a competitive advantage after graduation. Northeastern has partnerships with many small and medium-scale manufacturing companies and strong collaborations with large organizations such as GE, IBM, Raytheon, Dell EMC, Flex, Northrop Grumman, and Analog Devices.

Students have robust research opportunities through Northeastern’s multidisciplinary research centers and institutes, including its manufacturing infrastructure such as the George J. Kostas Nanoscale Technology and Manufacturing Research Center, the National Science Foundation Center for High-Rate Nanomanufacturing, and the Advanced Nanomanufacturing Cluster for Smart Sensors and Materials. Other related Northeastern University research centers and institutes are also available such as the Institute for the Wireless Internet of Things, the Institute for Experiential Robotics, and the Institute for Information Assurance. Northeastern also has partnerships with national research labs, who are involved in advanced manufacturing research, and several industry collaborations.

Program Goals

The MS in Advanced and Intelligent Manufacturing produces researchers for the development of advanced manufacturing technologies and leaders for managing advanced manufacturing enterprises.

Graduates of the MS in Advanced and Intelligent Manufacturing program can join as engineers at high-tech companies, become managers at government agencies, or pursue PhD degrees in advanced manufacturing at U.S. universities. Career opportunities are available in key sectors such as aerospace, automotive, computers, manufacturing, chemical processes, electronics, materials, controls, instruments, and power and energy systems.

The fourth industrial revolution, or Industry 4.0, is transforming manufacturing operations to advanced manufacturing by extending digital technology with interconnectedness using the internet of things, access to real-time data, and cyber-physical systems. Globally, nine out of ten companies are investing in digital factories*, and various U.S. federal agencies have collectively created the National Network for Manufacturing and Innovation Institutes (NNMII), referred to as Manufacturing USA, to invest in innovative advanced manufacturing technologies. Northeastern is a member of five NNMIIs. At the same time, according to Talent Board, there is a severe shortage of people trained in advanced manufacturing with 50% to 75% of people applying to positions unqualified, and there is an over 30% shortage of engineers, researchers, and scientists.

*Digital Factories 2020: Shaping the future of manufacturing

Academic Advising

We have a variety of advisors to help make your graduate career a success, so use the link below to determine which one will help you the best.

Admissions & Aid

Ready to take the next step? Review degree requirements to see courses needed to complete this degree. Then, explore ways to fund your education. Finally, review admissions information to see our deadlines and gather the materials you need to Apply.

Student Experiences

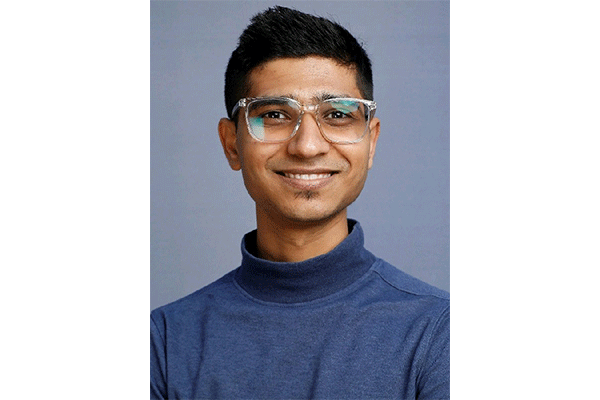

Mrudul Satbhai on Finding your Academic Niche

Mrudul Satbhai, MS ’25, advanced and intelligent engineering, completed his bachelors in India and came to Northeastern to pursue his interests in smart manufacturing. Among impressive research, co-ops, clubs, and a community of mentors and peers, Satbhai possesses a variety of successful projects and valuable skills that have set him up for success in the work force.

Improving Manufacturing with Innovative AI Solutions

Ajith Srikanth, MS’26, advanced & intelligent manufacturing, at his co-op with Van Dyk Recycling Solutions, worked on developing and designing innovative AI solutions to improve the manufacturing process.

Northeastern Team Wins Third Place at ASEM Case Competition

A Northeastern University student team, advised by MIE Associate Teaching Professor Himlona Palikhe, placed third in the 2025 Graduate Student Case Analysis Competition, hosted by the American Society for Engineering Management (ASEM).

2025 Laurel and Scroll 100 Inductees

Twenty-nine engineering graduate students were inducted into the Laurel and Scroll 100, a society established in 2024 to honor exceptional graduate and professional students across Northeastern’s global university system.