A better motor for the Mars Rover

In the world of robotics, identifying actuators that are strong and compact is probably one of the most important open technological problems yet to be resolved. More often than not, the mechanical elements that translate data into doing are big, rough, and generally unfriendly for use in everyday robotics, said Dinos Mavroidis, Distinguished Professor of Mechanical and Industrial Engineering at Northeastern University.

In the mid-2000s, Mavroidis’ lab set out to develop a new kind of actuator—small enough to sit inside the joints of prosthetic limbs, but powerful enough for everyday tasks such as lifting and walking.

Backed by two new grants—one from the National Science Foundation, the other from the National Aeronautics and Space Administration—Mavroidis’ team will work to tailor the technology for use in advanced space applications as well as everyday household robots.

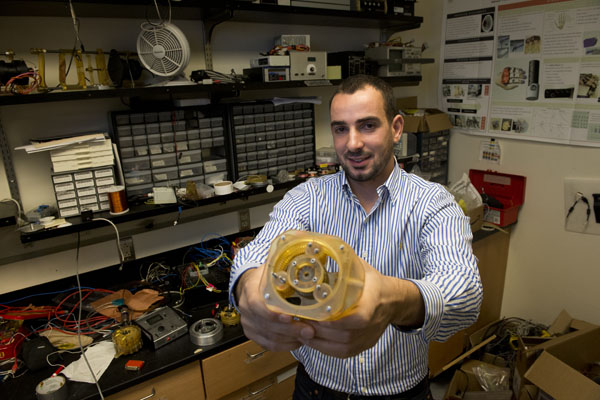

The gear bearing drive, or GBD, as the team’s unique actuator is called, consists of a motor embedded directly inside the gear transmission, allowing for cheaper, lighter, and stronger functioning. The GBD is a compact mechanism with two key abilities. It operates as an actuator providing torque and as a joint providing support. Back in 2006, Mavroidis and then graduate student Brian Weinberg developed the idea in collaboration with John Vranish, a NASA Goddard Space Flight Center engineer.

Elias Brassitos, a doctoral candidate in Mavroidis’ lab, will use funding from a Space Technology Research Fellowship to develop the GBD for use on the Mars Rover. “For space applications, everything needs to be lighter and stronger,” said Brassitos, who noted that the device would replace the entire joint assembly for the rover’s manipulator, the arm that extends outside the vehicle to collect rock samples and other things

“Mobile Robotics, particularly the use of rovers as part of a wider NASA exploration strategy, puts pressures on actuation technology,” said Brett Kennedy, supervisor of the Robotic Vehicles and Manipulators Group at the Jet Propulsion Laboratory in Pasadena, Calif. “We are always looking for ways to pack more torque, more power, and more functions into smaller packages,” added Kennedy, who has high hopes that the GBD will help them do just that.

First, Brassitos must design various GBD architectures, each of which might be good for different applications. He’ll design and build a prototype at Northeastern, and then assemble and test the device at the JPL.

While Brassitos works to develop the GBD for space, another graduate student will work to “commercialize it for earth.”

In collaboration with the startup company Foodinie, which aims to make robots for the modern household kitchen, doctoral candidate Andy Kong and Mavroidis are developing an off-the-shelf version of the gear bearing drive that inventors can use for a variety of applications. In some cases, the team will develop it for specialized needs as in the case of the Mars rover.

“There is a possibility for the GBD to be a source for innovation in the area of compact actuators for robotic systems,” Mavroidis said.