Locomotives, Ophthalmoscopes, and Mountain Bikes: A Northeastern Alum’s Impact

Main photo: Alumnus Morgan Misek (L) with his Trxstle business partner John Smigaj

Outdoor accessories and apparel company Trxstle’s founder and COO, Morgan Misek, E’08, mechanical engineering, has always been a designer and creator. In high school, he took drafting and 3d design courses, which led his instructor to recommend a few different colleges for mechanical engineering. Morgan Misek chose Northeastern’s College of Engineering because of the generous financial aid package offered and the strength of the co-op program. He says, “It was a unique aspect of Northeastern compared to other schools.”

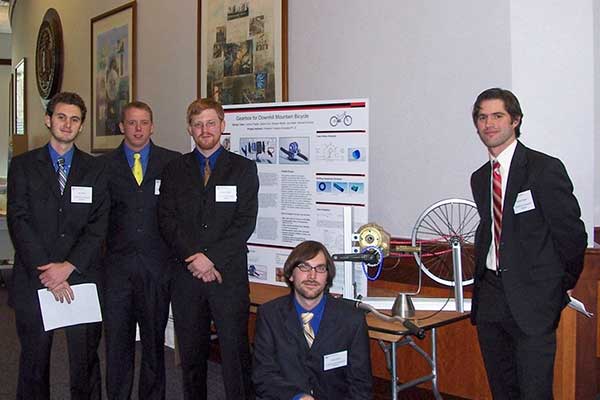

Morgan Misek’s team of Northeastern cyclers and classmate engineers who built the gearbox as their capstone project (L-R: Jay Seiter, Michael Witonis, Morgan Misek, Jesse Kuhn, and Josh Filgate)

Misek remembers and frequently references his geology of oceans and coasts class—“Professor [Peter] Rosen was a memorable and enthusiastic guy”—and his thermodynamics course. Misek’s capstone project with Gregory Kowalski especially left an impact on him. “Professor Kowalski was a huge proponent of our capstone project. We were the only team that had a self-proposed project to work on, which was a passion project of the Northeastern University cycling team: to design an internal gear box for a mountain bike. We patented it and won the contest. I remember some of the other students saying, ‘We knew you guys were going to win because you basically lived in the design lab.’” An avid mountain biker, Misek says, “I want to shoutout the Northeastern cycling team, those guys were my family away from home.”

For his first co-op, Misek worked at a company developing a blood transfusion process with complex centrifuge machines. He learned how to run a numerical control machine and a manual mill. “There was a lot of hands-on manufacturing and testing.” His second and third co-ops were both at Boston Engineering with their mechanical engineering team. As a services company, he worked on dozens of projects across many industries and using a variety of design techniques. “It was a fantastic place to learn and network. I went there full-time after NU with a job lined up. They knew me, I knew them, and we both knew what we were getting.”

Misek remained at Boston Engineering until his wife—a fellow Northeastern graduate from Bouvé College of Health Sciences—got a job as a nurse practitioner in Olympia, Washington. Moving to Olympia, Misek found a position at Hummingbird Scientific, which builds tools for electron microscopy, and after a few years joined Sygnet Rail Technologies, which built and designed locomotives.

In 2015, Misek went into work on his birthday only to learn that the company was shutting down. His friend and colleague engineer John Smigaj chatted with him about a self-employment program designed to encourage degreed Washington residents to start businesses. Misek says, “I’d always wanted to own my own business.” Misek and Smigaj formed a product design firm called Oak Avenue Engineering, where they leveraged Misek’s east coast network to pull in contract jobs. They completed design work on bike products and outdoor gear, industrial design products for pest control, and their largest project was for PlenOptika, who had designed and 3d printed an ophthalmoscope to measure vision loss for prescriptions in seconds. “Doctors around the world used it to easily prescribe glasses in poorer communities. We took the project from their prototype to a final product design. It felt really good to help people in need.”

Two years into Oak Avenue Engineering, Misek and Smigaj threw around the idea of scaling up, but they also had ideas for their own products. “After some brainstorming, we came up with the name Trxstle, which is our own outdoor brand that we launched in 2017.” After connecting with their local economic development council, they participated in a regional countywide program—“like a local Shark Tank”—and were the first business to get funded by that program. “We connected with one of the main investors, he’s an avid fly fisherman, he saw the products we were designing for fishing—the Convertible Rod Carry System—and he helped us go into production in 2018.” They had product for sale by the beginning of 2019. Trxstle assembles their products in a Montana facility, as well as quality control, packaging, and shipping.

Morgan Misek on a mountain bike in New Jersey

COO Misek and CEO Smigaj have encouraged each other’s outdoor hobbies. “John got me into fly fishing, and I got him into mountain biking. We launched our flagship bike product this year, the Geryon, a universal rack system for bike packing.” Next steps for Trxstle are expanding product lines, apparel designs, and expansions to their CRC system. “We get requests all the time, and we’re finally able to tick those boxes. We’ll be launching new accessories for the mountain bike system soon.” Misek attributes much of his success to his time at Northeastern and on co-op. “I would say the value of networking and work experience through the co-op program is equal to the value of the education.”